Home » Mining

Responsible

Mining

Management

Responsible Mining Management

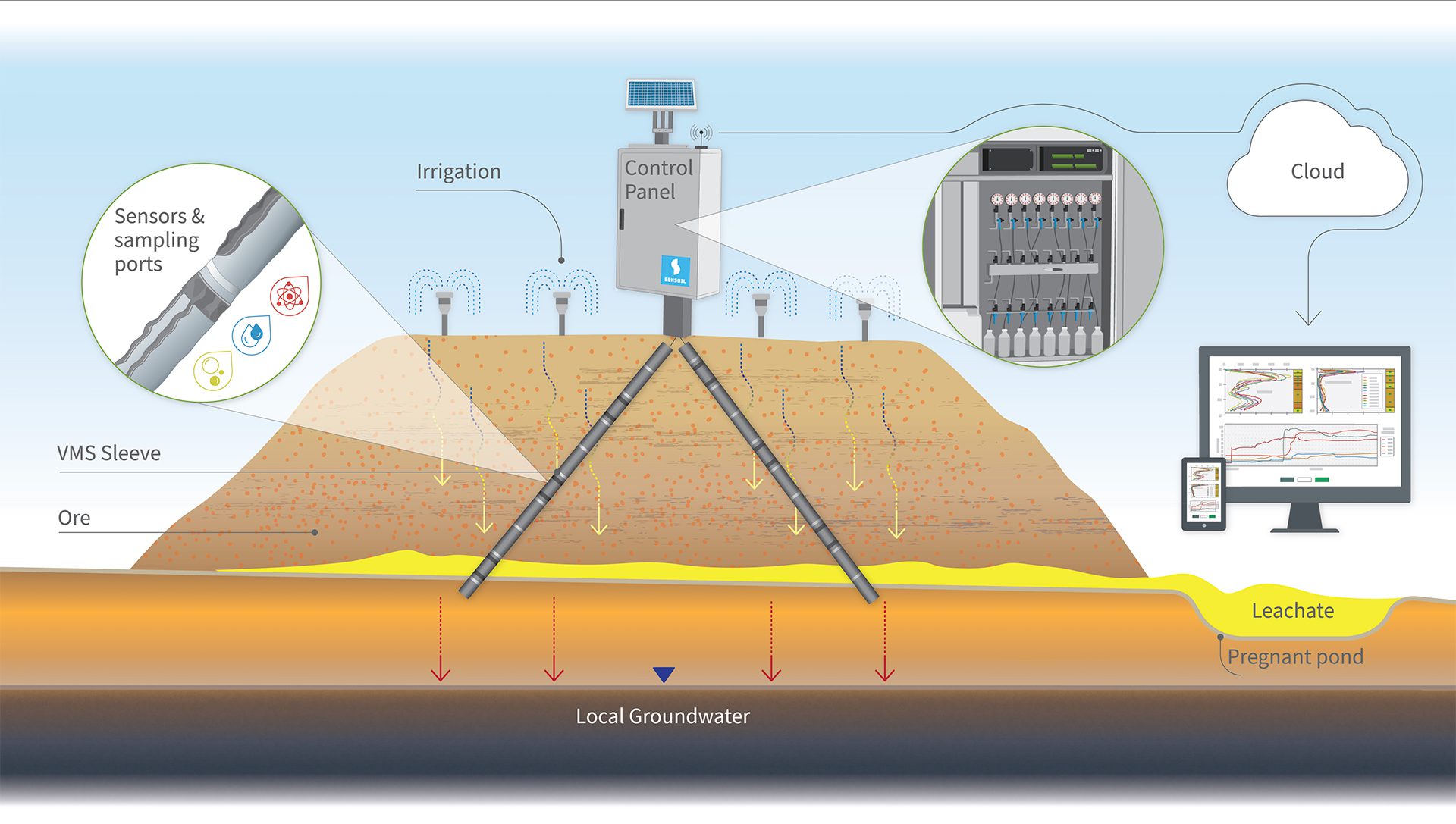

The global mining industry is growing, as demand for precious metals rises. Mining companies are required to raise profitability and productivity, while maintaining responsible, safe and sustainable mining processes. Smart mining and digitization will support increased safety, environmental and regulatory compliance, and enable proactive optimization of systems and equipment. Sensoil’s Vadose Zone Monitoring System™ (VMS) enables smart and responsible mining management. The VMS provides real time information on the hydrological and chemical properties of the percolating water across the unsaturated domain. VMS is a powerful tool that can serve all three mining aspects: Optimizing heap leach productivity, reducing subsurface pollution and enhancing tailing dam safety

The Challenge

The heap leaching method is a common extraction technique used in mining of metals such as gold, copper, silver and uranium. Optimization of heap leach production is a major economic challenge. Water percolation through the ore heap takes place in unsaturated conditions. Tailings as a by-product of the heap leaching method raise further challenges as they release contaminants to the environment. The pollution potential by mineral production from ore heaps is due to the application of large quantities of water during the process. This polluted water often leaks from the pad and production zone to the subsurface, infiltrates the vadose zone, and finally penetrates the local aquifers. The lag time between initiations of infiltration events of polluted water until appearance in observation wells, may span years to decades. Throughout the lag time, large pollution masses may accumulate in groundwater, reaching untreatable levels and causing irreversible damage to local water resources.

Tailings require large susceptible embankment dams to store increasing amounts of tailings, which consist mainly of wet sludge. This sludge is stored behind earthen dams. However, any erosion or instability in these barriers can lead to failing and potential collapse of the tailing dam, and release of tons of sludge. Unfortunately, around the world, dams are still collapsing, resulting in uncontrolled tailings spills and dangerous flow-slides leading to major human and environmental catastrophes.

The ability to monitor deep sections of unsaturated sediments, such as prevails in ore heaps, is relevant to all three of these challenges.

The Solution – VMS

Optimizing Heap Leach Productivity

Leaching efficiency of unsaturated sediment is much dependent on the ability to implement optimal hydraulic and chemical conditions in deep sections of the unsaturated sediment.

A typical heap leaching operation involves ore excavation, milling of the ore and heaping of the crushed ore on an impervious pad. The ore heap is then leached with a solvent, using irrigation systems. During percolation of the leaching solvent through the heap, the metal oxides dissolve from the crushed ore and drain down to the bottom of the heap. As a result, the drained solution (pregnant) is enriched with the desired metal, which is then processed.

The VMS provides real-time, in-situ monitoring of the actual conditions in the subsurface of the heap, providing continuous feedback on the efficiency of the infiltration process. Direct measurements of the temporal variations in sediment water content with respect to the irrigation cycles implemented on land surface may contribute dramatically to optimization of the leaching process. This is turn can save resources (water and chemical inputs) as well as increase mineral extraction efficiency. The VMS also enables sampling at will, of the percolating water across the entire ore heap.

Reducing Subsurface Pollution

The VMS enables real time identification of the water flow and contaminant transport in the vadose zone directly under the heap leach pads and production zones. Providing continuous data on the chemical and hydrological properties of the percolating water across the unsaturated domain, the VMS facilitates proactive responses to early warning on pollutant leaks to the unsaturated zone. Early detection of pollutant transport before contamination accumulates in the aquifer is crucial to prevent groundwater pollution (at untreatable levels).

Enhancing Tailing Dam Safety

To ensure tailing dam safety, regular inspections and maintenance of the dams are required. Implementation of the VMS provides continuous and real-time data on water content within the dam’s structure. Real-time, continuous monitoring of the embankments’ safety may enable proactive action, thus minimizing or preventing hazardous events.

Testimonial

“We (ICL Rotem Amfert Negev) uses VMS stations, developed and constructed by Sensoil and Prof. Ofer Dahan. Rotem Amfert produces phosphoric acid from phosphate rocks and sulfuric acid reaction, the by-product of the reaction is phosphogypsum…

…We operate the Sensoil VMS monitoring sleeves in our wet gypsum pond. The monitoring system allows continuous measurement of wet conditions and temporary sampling of water in the non-saturated medium in the area where the sleeves are located. Continuous measurement of changes in moisture content profile and chemical compositions of the soil water, enables assessment of the water flow from the settling pond, as well as direct measurements of the quality of the water that permeates the non-saturated water to the groundwater. This unique system, together with the help and knowledge of the owners and Prof. Ofer Dahan, grants us all the data we need for monitoring our gypsum ponds. The VMS already had an important use, in showing the authorities samples of water we took, which proves that the contamination is from another source and not from our cell.

We couldn’t have done it any other way.

We intend to use this system in all our ponds in the future.”

Mr. Tamir Kozlovski, Project Manager, ICL Rotem Amfert Negev